- Home

- >

- All DAIKO products

- >

- Maintenance Service

Maintenance Service

AN INNOVATIVE SERVICE FOR THE MAINTENANCE OF INDUSTRIAL PLANTS

Thanks to the experience gained over forty years, DAIKO is now able to also produce items in wear resistant plate built to the customer's design such as pipes, curves, cyclones, snails and fans and to provide a complete maintenance and construction service for mechanical parts subject to wear such as shredders, crushing mills, impellers, stellite knives and augers

Our productions

Cyclone with calming device for glass recycling plant

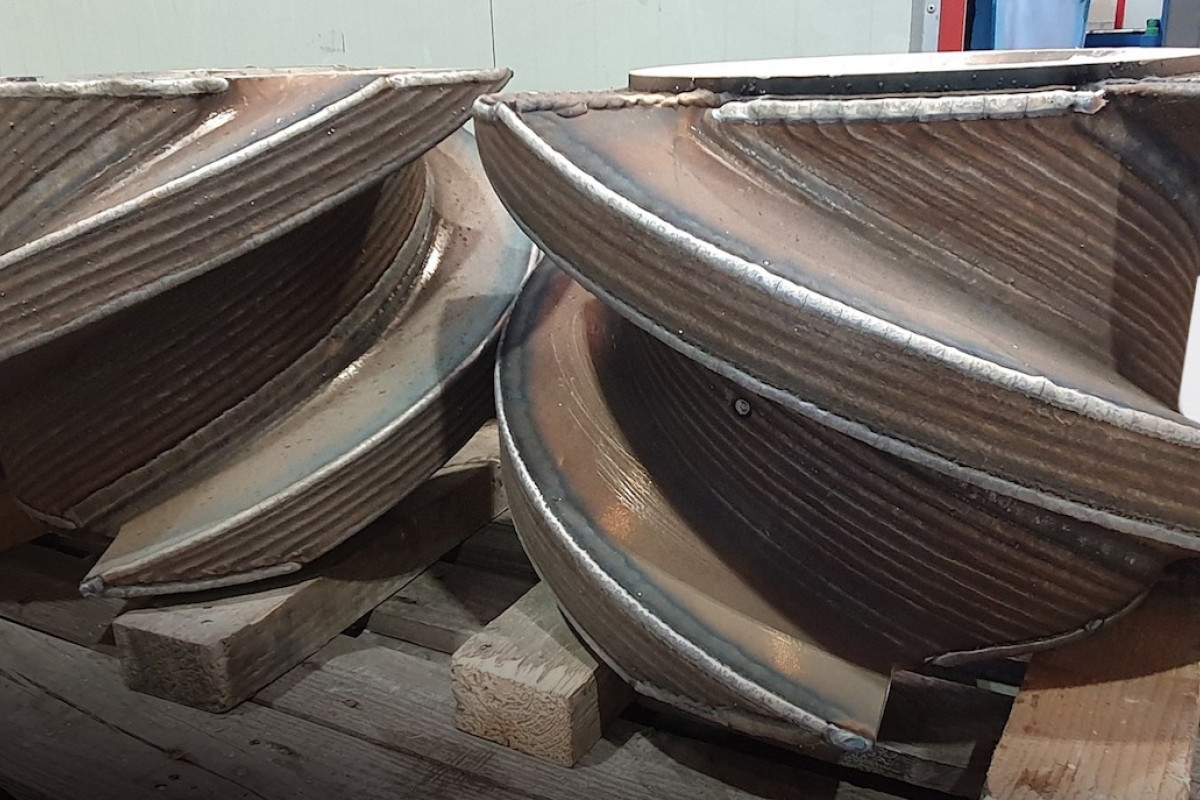

Semicone made of DAIKOPLATE

Two-outlet pipe in DAIKOPLATE

DAIKOPLATE tubes

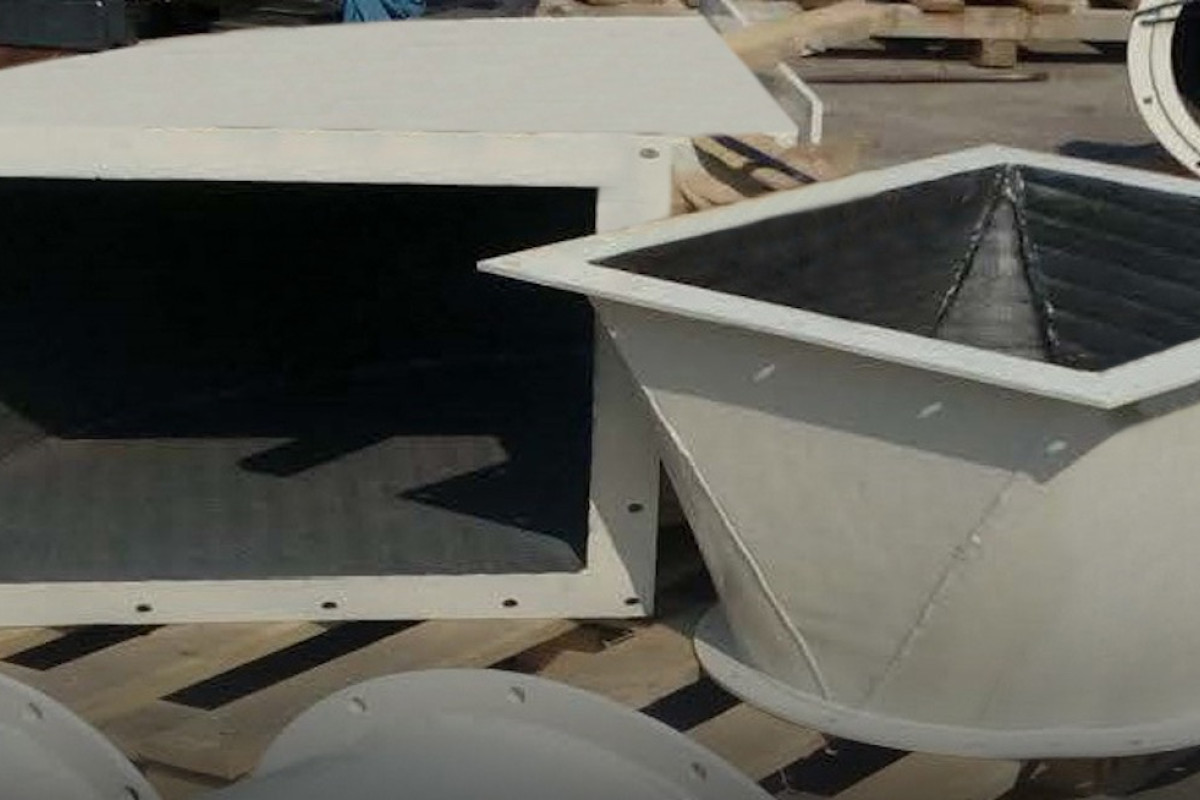

Powder and glass hoppers made of DAIKOPLATE

Restoration of press screws for wet waste

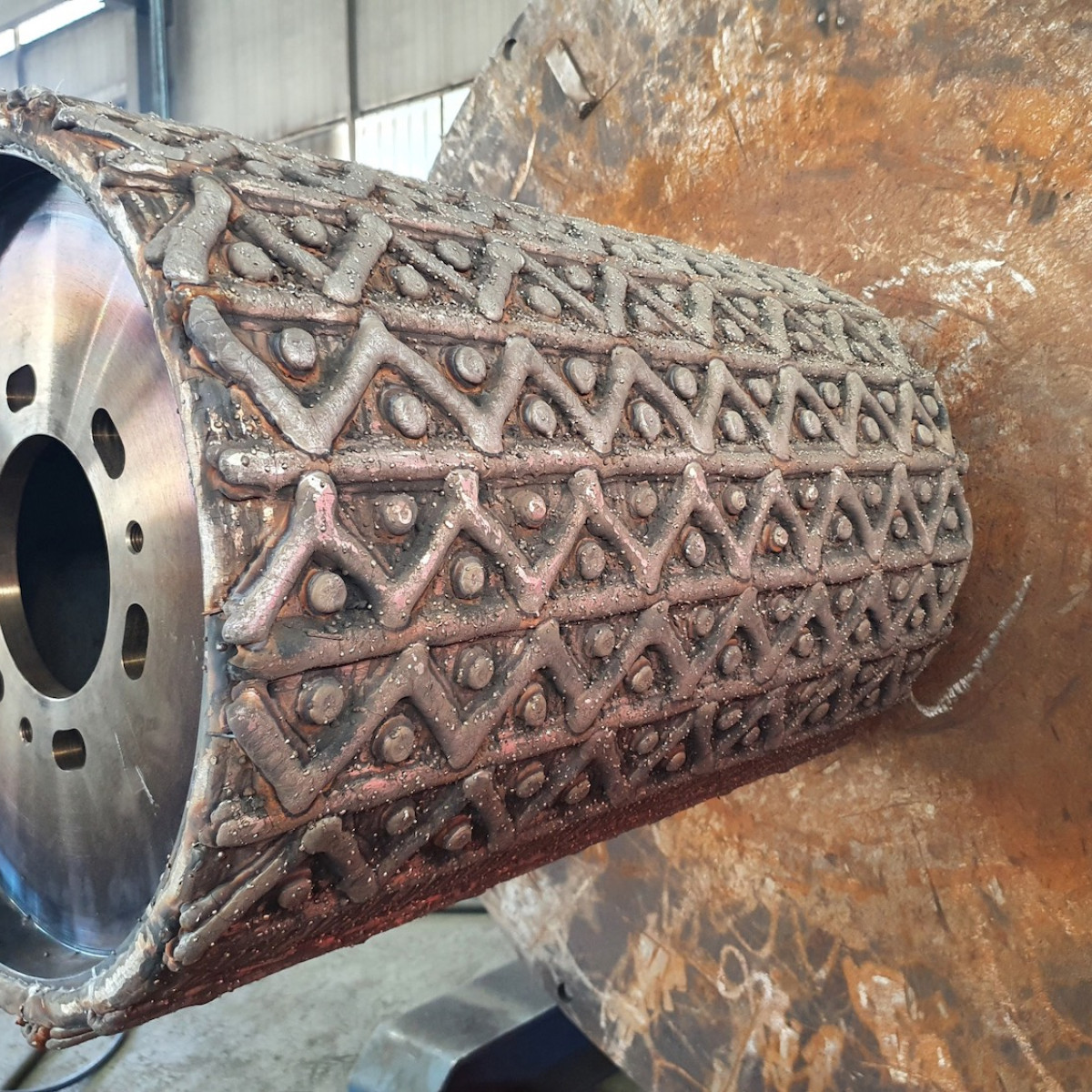

MSW shredder surfacing

Hot powder melting on bushing

Finished wear-resistant bushings

Maintenance carried out — before and after

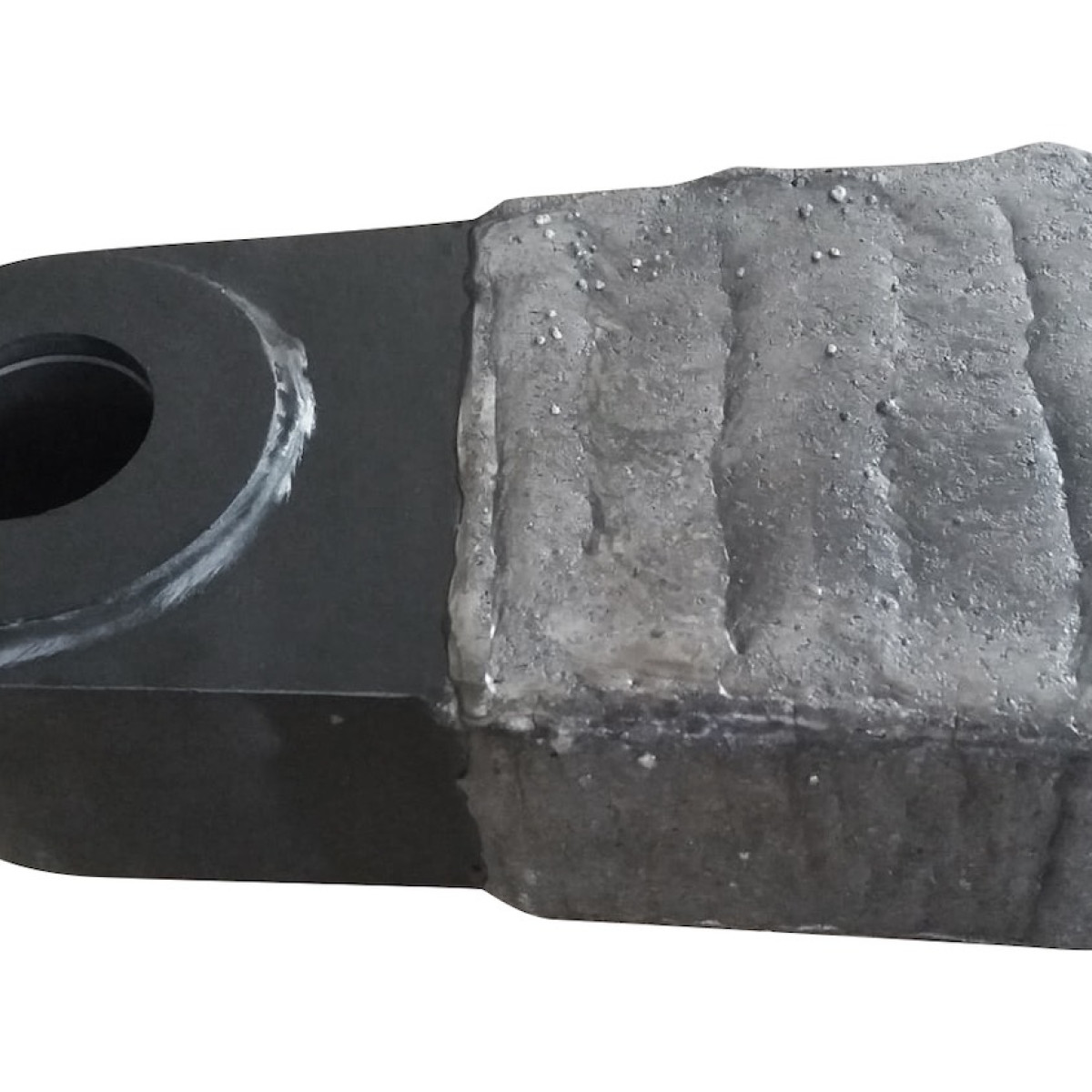

Hammer reconstruction with wear and impact resistant coating

Before

After

Waste shredder: before and after regeneration

Before

After

Primary grinding rollers restoration

Before

After

Extruder screws: before and after regeneration

Before

After